Solutions

Sensors in Extreme Areas

Sensors make our lives much safer and more efficient. They are the senses of cyber physical Systems (CPS, Internet of Things and Services) for connecting people and technology with their environment.

Within the fourth industrial revolution, they are becoming an important part of a connected and smart world. Thereby, more sensors rapidly proceed, even to extreme areas.

Industrial environments are often characterized by extreme interference and harsh conditions. These extreme conditions include high-frequency and electromagnetic interference, magnetic fields, high voltage, lightning and explosion hazard.

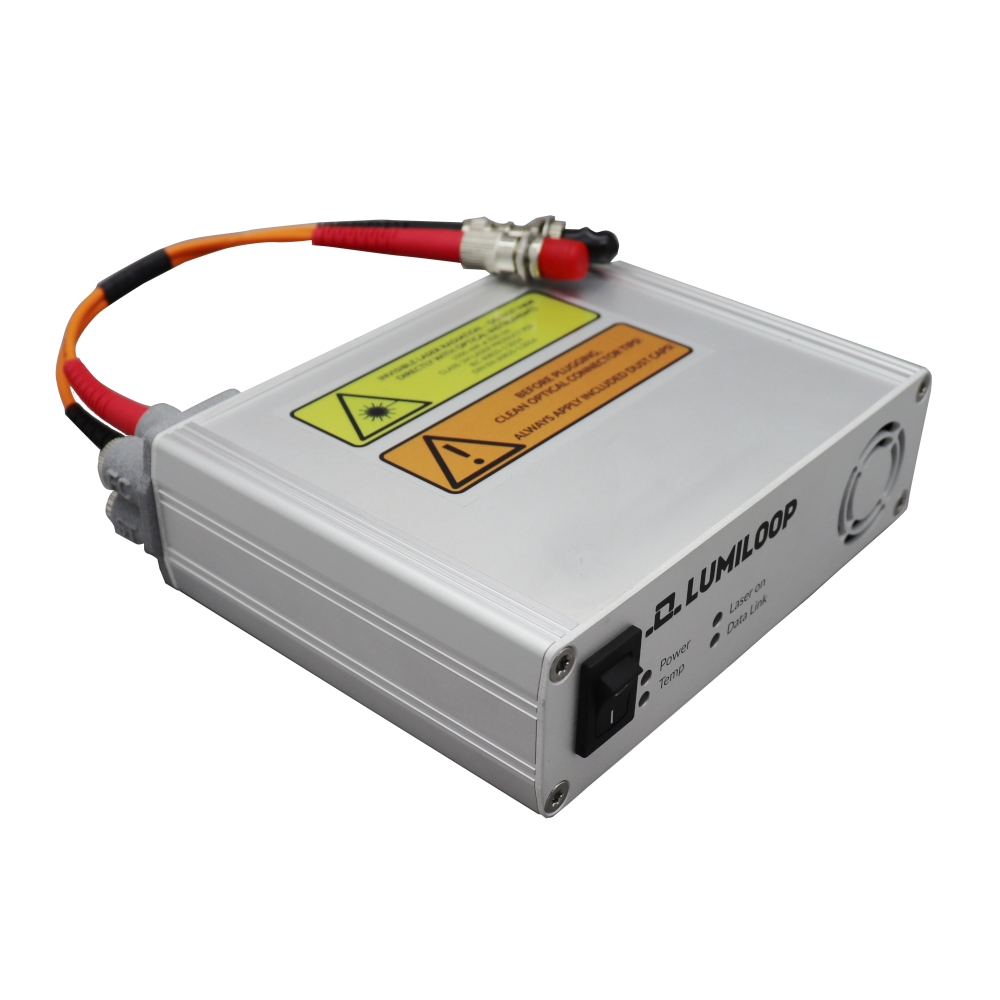

EMC Measurement Equipment

The Electromagnetic Compatibility (EMC) Testing has an increasing impact on companies in the future. Product design and product quality have to be compatible with international compliance standards.

This has a significant impact especially on the development of electric vehicles. An effective EMC shielding is one of the key factors for e‑mobility. Electromagnetic fields are moving in the focus to an extent, which did not exist in the recent past.

High Voltage Measurements

The grid expansion to “smart grids” requires intelligent feeding points for high-voltage grids. Monitoring and controlling of the entire energy supply system will become more complex and sophisticated. Not only the electrical parameters of the line current, but also operating and status information from transformers, inverters and switchgear need to be monitored. For voltages exceeding 4 kV such measurements require very elaborate and expensive safety precautions to protect man and machine against electric shocks.

Renewable energy plants, which are feeding the grid on a medium voltage level (20 kV), also require monitoring at many locations. At each entry point of the Smart Grid, e.g. solar installation, an inverter is necessary to convert the voltage to main voltage level. For voltages exceeding 4 kV, the triggering of the transistors is very costly. Nowadays, the applied control units limit the efficiency of the inverter. LUMILOOP systems will be an enabler for highly efficient inverter by reversing the numerous limitations of the present technologies for controlling transistors. A higher efficiency of the inverter automatically means higher profits during the feeding of the Smart Grid with current.

Besides the EMC related challenges of e‑mobility, high electrical voltages up to 1 kV occur on batteries, motors and controllers. The same affects railway vehicles with voltages up to 25 kV on overhead lines.

Security & Defense Technology

In case of failure or manipulation the patented self-monitoring and emergency shutdown ensures a safe, spark-free operation in explosive areas. For many applications, the laying of optical cables is more convenient than conventional explosion protection. In comparison to custom-built shielded cables, optical systems provide low-cost cable lengths up to one kilometer.

LUMILOOP offers a tap- and tamper-proof communication and power supply of sensors and low-power cameras for security and defense applications.

To supply sensors in hazardous areas such as tank or painting facilities expensive safety efforts are necessary. Especially the mining sector benefits from the patented power loop guaranteeing an explosion-proof shutdown time.

Aviation is another field of application for LUMILOOP Systems. The low weight of the optical cable and the explosion-proof enables the supply of sensors and monitoring of airborne fuel tanks.